JXSC Mining Machinery has a long history in mining area, and has acculated rich experience on small & medium scale mining and beneficiation. We work on offering equpment and EPC services for mine owner with small or medium scale processing plants, escorting efficient and safe processing performance in the global mineral resources industry with our reliable mining equipment and innovative solutions.

From its tough beginning, the business that started in 1985 went to win the trust both home and board, with mineral processing machines sold to over 100 countries and regions( such as USA, Canada, Australia, South Korea, Japan, Mexico, Chile, Congo, South Africa).

Visit customer success cases to see what changes will our help of experience and technical expertise bring. May our experience in the various minerals like gold, silver, diamond, copper, tin, coltan, iron, chrome, titanium, etc. do you a favor in the increasing profit and reducing risks.

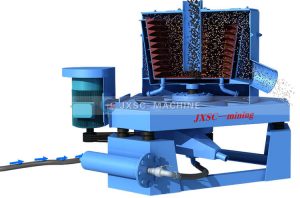

JXSC Mining & Beneficiation Equipment

Mineral Processing Solutions & Services

Get A Free Consultion Online, With Our Mining Experts

Mineral Processing Engineering Blog

Tin Ore Extraction

Brief history of extracting tin from tin ores In nature, the tin ore are existing in sand or alluvial raw material, this kind of tin ore is called sand tin or alluvial tin, those raw materials may be stone, sand, gravel, soil, sticky clay, some times with other magnetic iron, tungsten, ilmenite, hematite, monazite, zircon … Read more

Magnetic Separation Process

The magnetic separation process is mainly to carry out a three-stage magnetic separation treatment on the ore powder and then go through the wet material magnetic separation. The finished iron ore concentrate powder is obtained. Generally, the iron content of the ore is 35%. After magnetic separation by this method, the iron content of the … Read more

Niobium-Tantalum Ore Beneficiation

Tantalum and niobium ore beneficiation coarse separation is usually used the gravity separation method, also, the flotation, electromagnetic selection and electrometallurgical separation are used in a combined process, when dealing with powder or primary mud content of ore, washing and scrubber operations are essential, while the use of high-efficiency grinding and classification equipment to … Read more

Unmanned Mining: 5G+ Industrial Internet Realizes Smart Mine

Coal dust, the roar of machines, and the hard work of workers, these traditional coal mining scenes have become history in some coal mines in China. At present, the mining industry has become one of the most widely used fields of “5G + Industrial Internet“. According to statistics, there are about 5,300 coal mines in China, covering … Read more

Quartz Sand Beneficiation Process & Equipment

The beneficiation process of quartz sand is mainly impurity removal and purification. To remove a small or slight amount of impurities in quartz sand and obtain a highly difficult separation technology of refined quartz sand or high-purity quartz sand. The quartz sand process mainly includes quartz sand impurity analysis and impurity removal process, quartz sand purification … Read more

The Choice of Flotation Principle Process

The number of stages of the flotation process When determining the flotation process, the principle process (also known as the backbone process) should be determined first. The principle process only points out the principle scheme of the sorting process, which includes the number of separation stages, the sorting order of the components to be recovered, … Read more