JXSC Mining Machinery has a long history in mining area, and has acculated rich experience on small & medium scale mining and beneficiation. We work on offering equpment and EPC services for mine owner with small or medium scale processing plants, escorting efficient and safe processing performance in the global mineral resources industry with our reliable mining equipment and innovative solutions.

From its tough beginning, the business that started in 1985 went to win the trust both home and board, with mineral processing machines sold to over 100 countries and regions( such as USA, Canada, Australia, South Korea, Japan, Mexico, Chile, Congo, South Africa).

Visit customer success cases to see what changes will our help of experience and technical expertise bring. May our experience in the various minerals like gold, silver, diamond, copper, tin, coltan, iron, chrome, titanium, etc. do you a favor in the increasing profit and reducing risks.

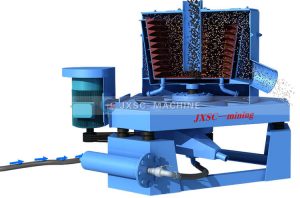

JXSC Mining & Beneficiation Equipment

Mineral Processing Solutions & Services

Get A Free Consultion Online, With Our Mining Experts

Mineral Processing Engineering Blog

Tungsten ore extraction processing

Extraction of tungsten Tungsten ore processing, that is separation and beneficiation of tungsten minerals from tungsten bearing ores. Tungsten concentrates are sent to smelters to refine the metals tungsten, tungsten carbide, tungsten alloys and tungsten compounds, while tungsten middlings is chemically treated to produce synthetic scheelite, ammonium paratungstate, tungsten powder and tungsten carbide. Minerals and … Read more

Chrome Ore Beneficiation Process

Study of Chrome Ore Magnetic Separation and Gravity Separation Process The chrome ore beneficiation processes include gravity separation, flotation, magnetoelectric separation and chemical beneficiation, etc. Because of the chrome ore composition that composed of one or more silicate, and the density difference between the chrome and silicate, the research both in home and aboard about … Read more

Rutile Titanium Flotation

Rutile Titanium Flotation Processing Description of titanium and rutile Rutile deposit can be divided into metasediment, eclogite, hydrothermal alteration, metamorphic altered rock and weathering-sedimentation. Natural rutile is the high-quality raw material for producing titanium dioxide, titanium sponge, titanium tetrachloride series products. The high-grade titanium dioxide, the product of rutile, has excellent indexes such as strong … Read more

Russian diamond mining industry

Russian Diamond mining and ore beneficiation Background Diamonds, originally a carbon lattice formed in high temperature and high-pressure environment in the earth’s mantle, came to the surface with kimberlite magma during volcanic eruptions millions of years ago. This mineral, which is of little industrial value, should have been just a kind of gemstone, becoming a … Read more

Factors Influence Ore Grinding Mill Efficiency

Factors Influence Ore Grinding Mill Efficiency Abstract The grinding efficiency is the most important parameter to evaluate machine performance. This article discussed the factors that influence grinding efficiency including article size to mill machine,milling medium,slurry rheological properties,underflow ratio,liner,grinding aid etc. The mill machine should be automatically controlled at a high level. the ball mill machine … Read more

Hydrocyclone Working Principle

Hydrocyclone is a grading device that uses centrifugal force to accelerate ore particle deposition. It needs the pressure to feed ore, so it consumes a lot of power but occupies a small area, cheap, the processing capacity is large, The classification efficiency is high, obtain very fine overflow product, mostly used in the second stage … Read more