Iron Mining Process

What is Iron

Iron (element #26, symbol Fe) is the most common metallic element in the universe. When pure it is a dark, silvery-gray metal. It is a very reactive element and oxidizes (rusts) very easily. The reds, oranges and yellows seen in some soils and on rocks are probably iron oxides. Iron is the third most common element making up the Earth. Iron is one of the three naturally magnetic elements; the others are cobalt and nickel. Iron is the most magnetic of the three.

The principle ores of iron are hematite, (70% iron) and magnetite, (72% iron). Taconite is a low-grade iron ore, containing up to 30% magnetite and hematite.

It is estimated that worldwide there are 800 billion tons of iron ore resources, containing more than 230 billion tons of iron. It is estimated that the United States has 110 billion tons of iron ore representing 27 billion tons of iron. Among the largest iron ore producing nations are Russia, Brazil, China, Australia, India and the USA. In the United States, large deposits are found in the Lake Superior region. Worldwide, 50 countries produce iron ore, but 96% of this ore is produced by only 15 of those countries.

Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. Raw iron is alloyed with a variety of elements (such as tungsten, manganese, nickel, vanadium, chromium) to strengthen and harden it, making useful steel for construction, automobiles, and other forms of transportation such as trucks, trains and train tracks. Due to the lower cost of foreign-made steel and steel products, the steel industry in the United States has had difficult economic times in recent years as more steel is imported. In 2013, the U.S. imported the following amounts of iron ore: Canada, 22%, Mexico, 10%, Korea, 10%, Brazil, 9%, and other, 49%.

Barytes Uses

In the United States, almost all of the iron ore that is mined is used for making steel. The same is true throughout the world. Raw iron by itself is not as strong and hard as needed for construction and other purposes. So, the raw iron is alloyed with a variety of elements (such as tungsten, manganese, nickel, vanadium, chromium) to strengthen and harden it, making useful steel for construction, automobiles, and other forms of transportation such as trucks, trains and train tracks.

About 98% of iron ore is used to make steel – one of the greatest inventions and most useful materials ever created. While the other uses for iron ore and iron are only a very small amount of consumption, they provide excellent examples of the ingenuity and the multitude of uses that humans can create from natural resources. Powdered iron: used in metallurgy products, magnets, high-frequency cores, auto parts, catalyst. Radioactive iron (iron 59): in medicine, tracer element in biochemical and metallurgical research. Iron blue: in paints, printing inks, plastics, cosmetics (eye shadow), artist colors, laundry blue, paper dyeing, fertilizer ingredient, baked enamel finishes for autos and appliances, industrial finishes. Black iron oxide: as a pigment, in polishing compounds, metallurgy, medicine, magnetic inks, in ferrites for the electronics industry. Major producers of iron ore include Australia, Brazil, China, Russia, and India.

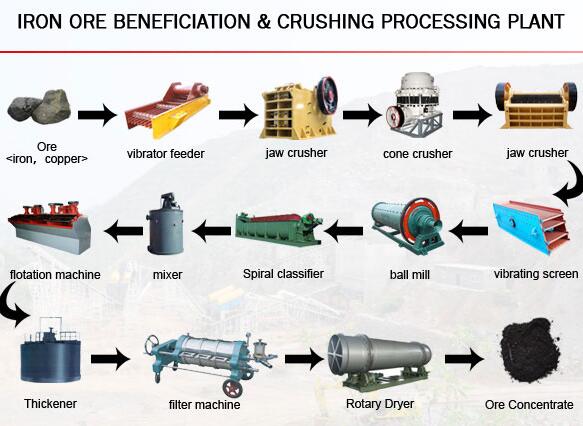

Iron Ore Mining Process

1. Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will be transferred to cone crusher by belt conveyor for secondary crushing; the crushed iron ore stone will then transferred to vibrating screen for classifying. After classifying, the parts whose size below the mesh size will be transferred away as final products, while the other parts will return to cone crusher, thus forming a closed circuit. Size of final products can be combined and graded according to your specific requirement.

2. The smaller crushed iron ore is fed to ball mill for grinding. Inside the ball mill, the crushed iron ore will grind the ore to about 0.2 mm with 3-inch steel balls.

3. This iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~-0.074 mm) going to froth flotation cells for recovery of iron.

4. In the magnetite processing plant, the process of flotation separation is replaced by magnetic separation. The minerals are conveyed to the permanent magnetic dewatering tank for concentrate and then concentrate will enter permanent magnetic drum for a second magnetic separation. The concentrate after filtration and drying are conveyed to the warehouse for storage.

Cases Study - Baryte Mining

150TPH Iron Ore Processing Plant in Malaysia

Material: hard rock type iron ore

Capacity: 150TPH

Country: Malaysia

Feeding size: 0-400mm

Raw mineral description:

1. Weak magnetic iron

2. Contains slime

3. Need crushing – washing – magnetic separation flow

Customers requirements:

1. The particle size of finished products requires 0-10mm

2. Concentrate grade of iron > 62%

---Read more---