The number of stages of the flotation process

When determining the flotation process, the principle process (also known as the backbone process) should be determined first. The principle process only points out the principle scheme of the sorting process, which includes the number of separation stages, the sorting order of the components to be recovered, and the number of sorting cycles.

What’s the number of stages of the flotation process?

It is the number of times the processed material is ground-flotation, then ground-re-flotation, that is, the number of times the grinding operation is combined with the sorting operation. The number of stages of the flotation process is mainly selected according to the cloth size of the components to be recovered and the siltification of the materials during the grinding process. The flotation process used in production practice is divided into one-stage, two-stage and three-stage, and the process of more than three-stage is rarely seen.

Grinding

Grinding once (change in particle size once), and then flotation is called one-stage. There is often more than one mineral in the ore, and sometimes several minerals are separated from one grinding. This is also called a section, but there are only a few cycles. The one-stage process is suitable for processing ore with uniform particle size, relatively coarse particle size, and is not easy to slush.

Stage Flotation Process

The stage flotation process is also called the stage grinding-flotation process, which refers to a two-stage or more flotation process, that is, the process of regrinding and re-floating the products of the first stage of flotation. The advantage of this flotation process is that it can avoid the material from being over crushed. The specific operation is to separate most of the components to be discarded under the conditions of the first stage of coarse grinding and regrind the obtained hydrophobic product or intermediate product. -Choose again. When this process is used to process materials with complex embedded components to be recycled, it can not only save the cost of grinding, but also improve the flotation index, so it is widely used at home and abroad.

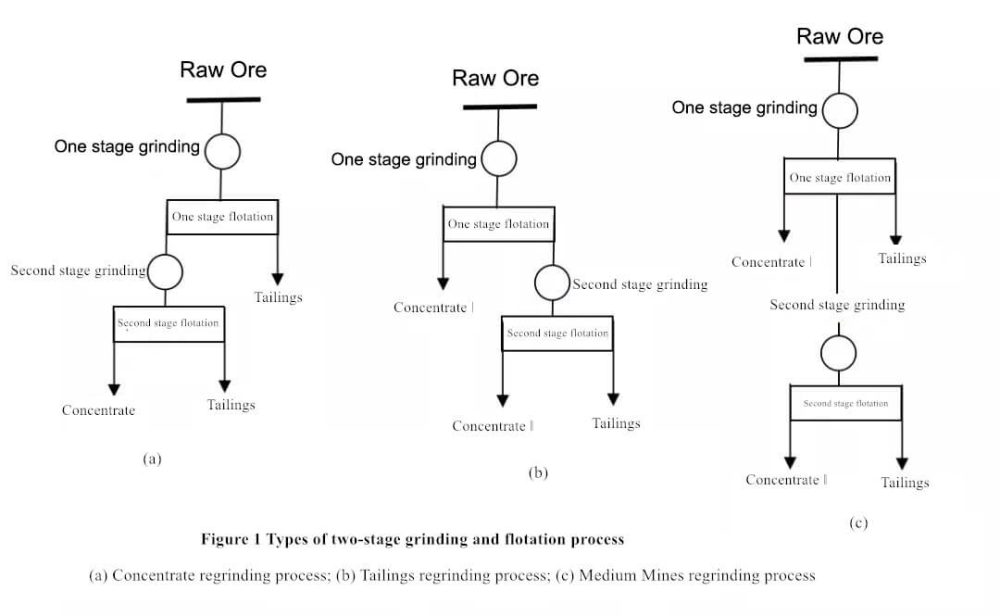

There are many types of stage flotation processes, and how to choose and apply them is mainly determined by the particle size and sludge characteristics of minerals. Taking the two-stage process as an example, there are three possible schemes: concentrate regrind, tailings regrind and medium ore regrind, as shown in Figure 1.

The concentrate regrinding process is suitable for ore with a finer grain size of useful minerals and coarse aggregates. Under rough grinding conditions, aggregates can be separated from gangue, and coarse concentrates and discarded tailings can be selected. The second stage Re-grinding and re-selection of a small amount of concentrate, this process is more common in multi-metal flotation; the tailings re-grinding process is suitable for ore with uneven distribution of useful minerals, or ore that is easy to oxidize and silt. Part of the qualified concentrate is separated from the lower part, and the tailings containing fine-grained minerals will be reground and reprocessed in the second stage; the middle ore regrinding process is suitable for minerals with fine-grained infestation. Part of the qualified concentrate and tailings can be obtained in the first stage. However, the middle ore contains a large number of conjoined bodies, so the middle ore needs to be re-grinded and re-selected.

Sorting Order and Sorting Cycle

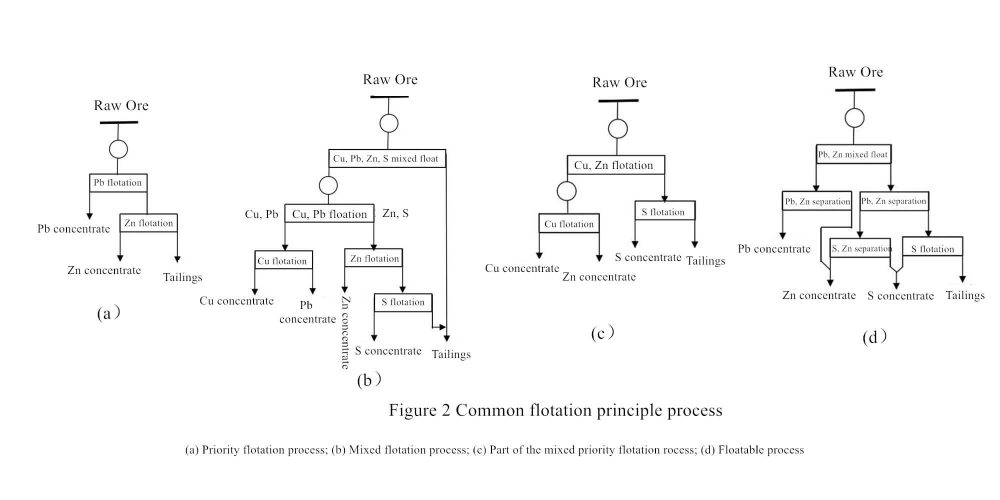

When determining the flotation principle and flow of polymetallic ore, in order to obtain several products, in addition to determining the number of separation stages, the selection order of various useful minerals should be determined according to the flot-ability of useful minerals and the symbiotic relationship between minerals. . The order of selection is different, and the principle processes are also different. The processes used in production can be roughly divided into four categories: priority flotation process, mixed flotation process, partially mixed priority flotation process, and other flotation processes, as shown in Figure 2.

The priority flotation process refers to the various components to be recovered in the material surface one by one in order, each time only one mineral is selected, other minerals are suppressed, and various products rich in a component to be recovered are obtained. Process flow. As shown in Figure 2(a), lead-bearing minerals float first, and then zinc-bearing minerals.

The mixed flotation process refers to a process in which all the components to be recovered in the material are floated together to obtain a mixed concentrate, and then the flotation separation is performed to obtain various products rich in a component to be recovered. As shown in Figure 2(b), the copper-lead-zinc-sulfur mixed concentrate is obtained through mixed flotation, and the copper-lead mixed concentrate and the zinc-sulfur mixed concentrate are obtained by flotation separation, and the copper-lead flotation separation and zinc are further carried out. Sulfur flotation is separated to obtain copper concentrate, lead concentrate, zinc concentrate, and sulfur concentrate. This process is suitable for ore whose useful minerals are in aggregate, with coarser particle size, and the float-ability of different useful minerals are close, and the tailings can be discarded under rough grinding conditions.

The partial mixing priority flotation process refers to mixing the flotation part of the components to be recovered from the material first, and suppressing the remaining components, and then activates and floats other components to be recovered, and the mixed concentrate that floats first is then subjected to flotation After separation, a process flow of a product rich in a component to be recovered is obtained. As shown in Figure 2(c), first mixed flotation to obtain copper-zinc mixed concentrate, mixed concentrate and then flotation separation to obtain copper concentrate and zinc concentrate, mixed flotation tailings, and then flotation to obtain sulfur concentrate. Copper and zinc-bearing minerals are preferential flotations compared to sulfur-bearing minerals, so it is called the partial mixed preferential flotation process. This process can be used when several minerals in the ore have similar float-ability, but some minerals have different float-ability.

The equal-float-ability process refers to the process that floats the recyclable components with similar float-ability together and then separates them. It is suitable for complex polymetallic sulfides that include two parts, easy to float and difficult to float, in the same mineral. mine. As shown in Figure 2(d), in the flotation of lead sulfide-zinc ore, zinc has two minerals that are easy to float and difficult to float, so the equivalent floatation process can be considered. The zinc and lead come out together. Its characteristic is that it can avoid the forced inhibition of the preferential flotation on the easy-floating zinc, and the forced activation of the mixed flotation on the difficult-floating zinc, which can reduce the consumption of chemicals, eliminate the influence of residual chemicals on the separation, and is also conducive to separation. Improved indicators.

The sorting cycle (or flotation circuit) refers to a group of flotation operations included in the selection of a certain final product, such as rough selection, sweep selection, and selection. Metals (or minerals) are named. Figure 2(a) shows a one-stage two-cycle process with a lead cycle (or lead loop) and a zinc cycle (or zinc loop). Figure 2(c) shows a two-stage three-cycle process with copper-zinc, copper, and sulfur cycles.