Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue and sewage treatment. Magnetic separation utilizes powerful magnets to draw ferrous metal contaminants out of the product line, attracting them to the magnet surface and ensuring they do not re-enter the product stream. The strength of the magnetic field means that a constant flow of product, no matter how fast, will not be able to dislodge the ferrous material from where it was originally trapped.

As the main equipment and carrier of magnetic separation, magnetic separator achieves separation using magnetic force and mechanical force on ore particles in the magnetic field, and the effect is obvious.

Type of magnetic separators

1. Wet Drum Magnetic Separator

It is suitable for separating strong magnetic minerals and the pulp concentration before filtration or regrinding. The most commonly used magnetic separation equipment in mineral processing plants. For the roughing operation, the weak magnetic separation operation before the strong magnetic separator and the enrichment operation, a large-diameter magnetic separator with a high magnetic induction intensity should generally be selected. The selection operation should adopt a magnetic separator with a low magnetic induction intensity.

For fine-grained minerals, the interaction between particles is enhanced. There are serious inclusions between magnetic and non-magnetic substances. If dry separation is used, it is difficult to remove the magnetic substances. Generally, wet magnetic separation is required.

2. Three-disc Magnetic Separator

It is an essential beneficiation equipment for separating weak magnetic minerals and rare metal ores. There are two types of three-disk belt magnetic separators. The dry-type three-disk strong magnetic separator is suitable for separating various magnetic mineral mixed ores. According to the magnetic difference of minerals, the magnetic field of different strengths can be formed by adjusting the excitation current of the disks at all levels to separate the minerals. It is also possible to adjust the induction distance between the disks at all levels and the mineral particles to be selected to obtain different magnetic field induction intensities to achieve one-time separation of various minerals.

This equipment is widely used in dry separation of iron ore, monazite, tungsten-tin ore and other related minerals. It can separate strong magnetic, weak magnetic, non-magnetic and other minerals simultaneously. It can be adapted to dry operations in water-deficient mining areas.

3. High Intensity Magnetic Separator

The strong magnetic separator is an upgraded product of the dry iron remover developed based on the original dry iron remover by improving the magnetic field strength and the arrangement of the magnetic blocks. Its magnetic system is all made of high-performance rare earth NdFeB materials and high-quality ferrite materials, with high magnetic field strength (up to 12000 Gauss).

For each group of magnetic media, the direction of flushing the concentrate is opposite to the direction of ore feeding, and the coarse particles can be washed out without passing through the stack of magnetic media, thus effectively preventing the blockage of the magnetic media. The double high advantages of high concentrate grade and high recovery rate have been realized.

4. Plate Magnetic Separator

The plate area is large, and the material flows evenly in the entire magnetic field area. The contact area between the material and the magnetic field and the number of rolls of the material in the magnetic field are increased. High-performance NdFeB magnetic material, unique design of magnetic circuit, high surface magnetic field can reach 15000GS.

Adjusting the slope according to the material condition can achieve a good iron removal effect. It is mainly used for iron purification of quartz, feldspar, nepheline ore and kaolin. It can also be used to separate red ore (hematite, limonite, siderite, etc.), manganese ore, ilmenite, wolframite and other weak magnetic metal ores.

Magnetic separator function

1. Mineral sorting - improving quality

It is mainly used for magnetite, limonite, ilmenite, etc., and can separate elemental minerals from gangue and sediment. Improve the quality of minerals and provide basic raw materials for industrial and mining enterprises.

2. Media recovery - energy saving and environmental protection

Mainly used for dense medium coal washing, sewage treatment, etc. The magnetic separator can recycle the magnetic medium powder used in the production process, which greatly improves production efficiency. Reduce floor space and reduce labor costs.

3. Mineral purification - high utilization rate

It is often used in quartz sand, potassium feldspar, albite and other industries. A magnetic separator separates the iron impurities in the minerals. It can improve the purity of minerals and is an essential production link.

Mineral Magnetic Separation Process

Among them, the most magnetic is magnetite. The demand for iron ore by various iron and steel enterprises has grown rapidly, further stimulating the development of the iron ore beneficiation industry. Magnetic separation is one of the main beneficiation methods of iron ore beneficiation, and magnetic separator is the main equipment of this method.

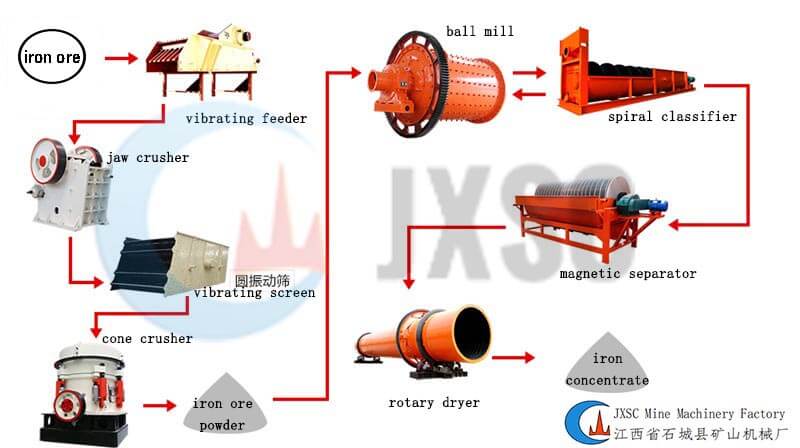

The entire magnetic separation process of ore dressing mainly includes three stages: crushing stage, ore grinding stage, and sorting stage. The main equipment used are jaw crusher, ball mill, spiral classifier, magnetic separator, etc., and then properly configured with feeder, conveyor, etc., it can be equipped with a complete magnetic separation production line. The equipment used in this production line can be increased or decreased according to the actual situation.

JXSC provides equipment suitable for various mineral processing plant applications, with its solid structure, magnetic separators that can be customized for multiple production capacity.