Extract gold from its ore has a long history in our human history, which can be dating back to sometime around 6000-3000 BC. And we may still remember some notable Gold Rushes in recent centuries.

In the modern mining industry, washing and extracting gold is not a one-off process. It needs some significant washing process and steps, and it’s washing processes is determined by the type and grade of gold mines. JXSC mine machinery factory with more than 20 years of practical experience of debugging gold dust washing equipment, so we have summarizes the 4 processes of gold ore washing and extracting, we hope it could be helpful for you.

1, Screening

The first process of gold extraction is screening, because the presence of large gravel will affect the efficiency of gold washing and damage the washing equipment, and this gravel even does not contain gold at all, so the first process is to screen the gravel from the gold ore, usually screening the gold deposit with a simple and practical screen is a good choice. (Note that the screening here is only a coarse sieve, the purpose is to remove the excessive gravel, and in the process of screening, also the gravel surface needs to be washed with water to ensure that the soil is washed through the sieve to avoid the loss of gold wrapped in the soil. )

2, Mud removal and disintegration

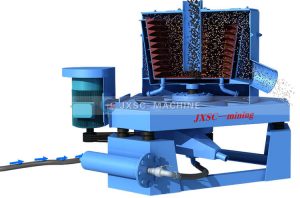

After the initial screening, the influence of large gravel on the gold selection process has been removed. The second process is desludging and disintegration. Desludge and disintegration actually doing the same job, that is, by sand-washing, mechanical scrubbing and other progress, the gold and mud in the mine are fully diluted to prevent the gold from being wrapped in the soil, this ways make the gold to be freed so that the gold can be recovered.

There are many methods for de-sludge and disintegration. The most common ways is washing, The mud with high mud content is usually washed by a cylinder washing machine or spiral washing machine. And the mud with low mud content is washed with trommel screen and then screening.

3, Gravity Separation

The third process is the sorting process. Gravity separation method is the most important and the only method for gold ore beneficiation. The common equipments used in the gravity separation method are chute (eg vibration chute, fixed chute, agitation chute), jig concentrator, shaker table, centrifuge, etc. Among them, only the chute and the jig concentrator are used for rough selection.

The advantage of the rough selection is that the processing volume can be very large, but the disadvantage is that the recovery rate may not too high, while the jig concentrator can achieve a high recovery rate but the processing capacity is small and the process is more complicated than the chute. And the gravity separation equipment such as shaker table and centrifugal gold separator is mainly used for the selection of gold and gold ore mines. It is an equipment for selecting the coarse concentrate from the jig concentrator or chute.

4, Selection

The selection method of the gold deposit is mainly gravity separation and amalgamation. The gravity separation method is to further enrich and purify the coarse concentrate of the jig concentrator and the chute with a shaker table or a centrifuge, and the gold shaker table can obtain the final height. Purity gold powder, but the loss rate is high, the centrifuge enrichment is relatively large, but pure gold cannot be obtained. Therefore, many people in the gold selection process still use the amalgamation process, and the amalgamation method is not only simple and convenient but also has a high recovery rate.

After the selection, the high-grade gold powder can now be directly smelted into gold ingots. That’s all the entire process of gold dust washing and extracting.