Jig Concentrator

Jig concentrator

Jig concentrator is one of the important gravity separation equipment, which use the different gravity of the raw ore composition to separation materials. The bigger the density difference and the specific gravity difference of raw ore, the better the separation effect.

Why Choose JXSC Jig Machine

- The Screen Mesh is made of manganese steel.

- The gear and eccentric gear of the gearbox adopt 45 # steel which quenching reach.

- GeShi Motors.

- The membrane tympanic uses natural rubber material.

- Thick steel plate. Good spring.

Capacity: 1-30 TPH

Application: It Mainly uses for separation alluvial gold, tungsten, tin, diamond, tantalum-niobium ore, chrome ore, manganese ore, ilmenite, and some poor ore, such as fluorite, garnet, cinnabar, etc.

Our jig machine has one or two gear boxes. In general, the feed particle size is relatively fine such as 3-5mm, the machine with a gearbox is ok. Feed particle size larger, it uses two gearboxes. The feeding minerals can is wet and dry. But feeding the dry mineral, the separation effect will better.

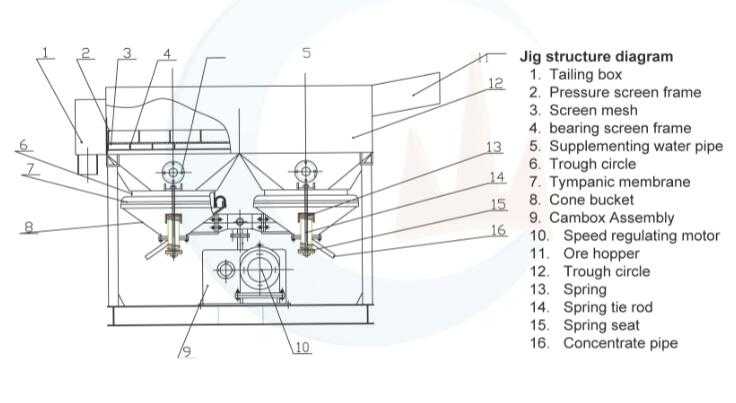

Main parts: Rubber diaphragm, rocker arm, water separator, transmission device, connecting rod, storage bucket, jig room, frame, diaphragm room, ore discharging stopcock, etc.

Types of the mineral jig

Eccentric connecting rod jig (plunger jig and diaphragm type jig), non-plunger jig, Hydraulically-driven jig, movable sieve jig/buddle jig.

At present, the main use of mining concentrators is diaphragm jig, and that of the coal industry is a non-plunger jig and movable sieve jig.

The diaphragm jig mainly used to separate coarse disseminated ore, and are used mostly in the tungsten, tin and other rare metal ore mines. The material should be screened before go into the jig machine, of which capable process particle size between 0.5mm - 16mm.

The trapezoidal jig has a larger processing capacity and can process the particle size of 50-0.25 mm. It has been widely used in tungsten, tin, and iron ore concentrators in China.

Jigging Machine Working Principle

According to the beneficiability and quality of the raw ore, the jigging machine makes the mixture of ore particles with different specific gravity to be stratified according to specific gravity in the flow of vertically moving variable speed medium (water or air). The ore particles with small specific gravity are located in the upper layer, and the ore particles with large specific gravity are located in the lower layer.

The medium used for jigging is water or air. The use of water as a jigging medium is called hydraulic jigging; the use of air as a jigging medium is called wind jigging. Hydraulic jigs are more commonly used, and wind jigs are used only in dry areas where water is scarce.

Uganda 100-TPH Coltan Mining Plant

Uganda 100-TPH Coltan Mining Plant

Mozambique 100TPH Alluvial Gold Mining Plant

Mozambique 100TPH Alluvial Gold Mining Plant

What should you do before running a gold jig machine?

1. Firstly, take a detailed investigation into the particle size range and the dissociation of target mineral monomers. The heavy sand with high content may increase the difficulty of jigging separation. It is difficult to separate the heavy sand with the size smaller than the screen hole in the next step. On the contrary, the heavy sand with the size larger than the screen hole will settle down in the layer, when there is more and heavier sand, the jigger can work effectively only when the sand and target minerals are removed from the bed by stopping the machine.

2. As for the muddy material, it is necessary to carry out desliming and classification processes before the material enters the jig machine. How to design the complete mineral processing plant? JXSC engineer team respond detailed online.

3. Under the condition of a large jig room, a small stroke, and insufficient water drum power, the gold mineral jig is losing the normal working function because of the piling up layer bed.

4. Make sure that the required pressure and sufficient amount of water are added to the Jig, especially in the dry season. In addition, the silt content in the water should be reduced as much as possible. The constant pressure water tank, which can not only effectively settle the silt, but also remove the silt conveniently, should be used especially for the dredging operation in the upstream of the river.

5. Pay attention to the selection and determination of artificial bed stone particle size, density and other characteristics.

Tech Specification

| Model | Jig Area (M2) | Stroke (R/Min) | Feeding size (mm) | Hutch Water ( T/H) | Pressure Water (kg/cm2) | Capacity (T/H) | Power (KW) | Overall dimensions (mm) | Weight (T) |

| JT0.57-1 | 0.57 | 60-160 | <6 | 1-2 | ≥0.3 | 1-2.5 | 1.5 | 1560x820x1550 | 0.612 |

| JT1-1 | 1.04 | 60-160 | <10 | 2-3 | ≥0.3 | 4-10 | 2.2 | 1322x1190x1915 | 0.9 |

| JT2-2 | 2.28 | 60-160 | <10 | 2-4 | ≥0.3 | 8-15 | 3 | 3225x1550x2150 | 1.637 |

| JT4-2 | 4 | 50-125 | <10 | 4-8 | ≥0.1 | 8-16 | 7.5 | 4240x1990x2750 | 4.6 |

| JT4-2A | 4 | 50-125 | <10 | 4-8 | ≥0.1 | 8-16 | 8 | 4240x1990x2750 | 4.6 |

| JT5-2 | 4.86 | 80-120 | <10 | 4-10 | ≥0.1 | 10-20 | 7.5 | 3940x2006x2580 | 4.6 |