Titanium Mining Process

Titanium is a rare metal that because of its dispersal and hard to extract. Also a silver-white transition metal. Its features are lightweight, high strength, resistance wet chlorine corrosion. Titanium is found in ore, such as Rutile and Ilmenite.

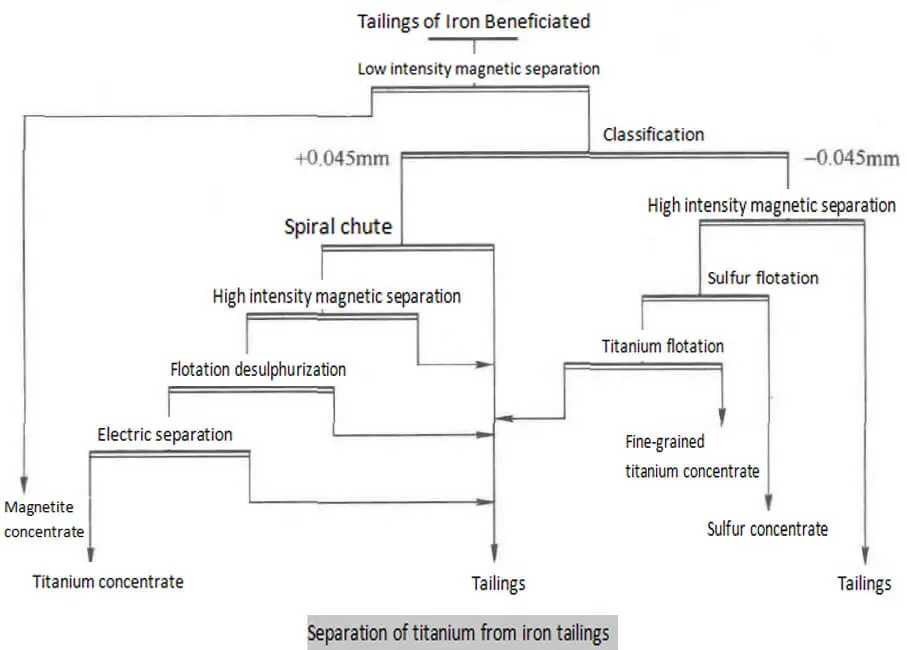

Extraction of titanium from ore is called the titanium mining process. Two types of titanium process: Gravity separation - Magnetic separation - Flotation, and Gravity separation - Magnetic separation- Electric separation. Related equipment: Jaw crusher, ball mill, magnetic separator, spiral separator, spiral chute, dryer, vibrating feeder, vibrating conveyor, etc.

JXSC build a close relationship with manganese mining plant in Australia, Brazil, Myanmar, India, Ghana, Mexico, Ukraine, South Africa. offer qualified mining equipment to mining companies since 1985.

Titanium Processing

Titanium processing needs several steps such as crushing, grinding, screening, magnetic separation and drying.

1. Raw ilmenite ore(or Rutile) is sent to jaw crusher by vibrating feeder for primary crusher and secondary crushing.

2. Entering the circular vibrating screen is screened, and the qualified ilmenite is sent to the ball mill for grinding processing.

3. The ground Ilmenite pulp is sent to the spiral separator for classification and washing, The materials which particle size does not meet the requirements need to be returned to the ball mill for further grinding. And the meets are sent to a magnetic separator for magnetic separation processing.

4. The concentrate after the magnetic separator is sent to a dryer to be dried and dehydrated. Then we get the dried concentrate powder material.

The beneficiation process of titanium depends on the nature of the material. Because the density of titanium ore is larger than that of gangue minerals, it can be used for pretreatment or rough selection tailing; magnetic separation method is widely used in the concentrate separation of titanium-containing minerals; when coarse concentrate contains ilmenite, rutile and non-conductive minerals such as zircon, it can be separated by electric separation; flotation method is used for sorting of primary titanium ore, especially for sorting fine-grained titanium ore.

1 Gravity separation

The gravity separation method has received much attention because of its low cost and eco-friendly characteristics. Shaker tables are widely used in ilmenite ore dressing, especially in small mines where a shaker is used to obtain a qualified concentrate. With the shaker process, the grade of ilmenite up to 48.82% and the recovery rate over 76%.

2 Electric separation

Electric separation popular in the production of titanium concentrate, the electric separator is the main electric titanium mining process equipment.

3 Magnetic separation process

Magnetic separation includes weak magnetic separation and strong magnetic separation. The role of weak magnetic separation is to separate the titanomagnetite remaining in the magnetic separation tailings to facilitate the smooth magnetic separation. The purpose of strong magnetic separation is to discharge qualified tailings, increase the selected grade of titanium flotation, and reduce the amount of titanium flotation. The high-gradient magnetic separator can effectively recover the fine-grained ilmenite in the ore, and can throw away some of the fine mud in the ore, thereby achieving the purpose of rough selection and tailing of the original ore. The ore is treated by a strong magnetic pre-selection process, and the grade is improved, which lays a foundation for the subsequent flotation to obtain the final titanium concentrate. The high gradient magnetic separator can refine the concentrate, which can reduce the grade of re-election concentrate, which is beneficial to improve the recovery rate of re-election and thus improve the recovery rate of the entire titanium mining process concentrator.

4 Flotation process

Flotation separation of primary titanium-bearing ores is an effective method for recovering fine-grained ilmenite, sometimes used in the selection of coarse concentrates. Before the ilmenite flotation process, select sulphide minerals by flotation machine firstly. The iron ore beneficiation plant mainly uses a mechanical agitated flotation machine. The aeration and agitation of the slurry of the machine are realized by mechanical agitator (rotor and stator group, so-called aerated stirring structure).

The agitated agitator of the mechanical agitation flotation machine has pump-like suction characteristics. In addition to self-priming air, it can also self-prime the slurry. mechanical agitation flotation machine has obvious superiority and flexibility in process configuration, has been widely used in the titanium mining process and mineral beneficiation plant.

Titanium mining process plant equipment list

| No. | Equipment name | Unit | Qty | |||||

| 1 | Vibrating screen | SET | 2 | |||||

| 2 | Spiral Classifier | SET | 1 | |||||

| 3 | Spiral separator | SET | 10 | |||||

| 4 | Strong magnetic separator | SET | 1 | |||||

| 5 | Scrubber washer | SET | 3 | |||||

| 6 | Vibrating feeder | SET | 1 | |||||

| 7 | Flotation | SET | 2 | |||||

Pre-sales service:

We provide you with the prophase plan, process flow design, and manufacturing equipment according to your special demand.

Sales service:

Send technicians to the job site guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sales service:

We will regularly pay a return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

Lifelong service:

One year warranty to make sure your machine runs constantly. Always offer lifelong service and provide spare parts for a long term.