Rare Earths Mining

What is Rare Earths

The rare earths, or rare earth elements (REE), are a relatively abundant group of elements consisting of scandium, yttrium, and the 15 elements of the lanthanide series of the periodic table.

Scandium (Sc) is the lightest rare earth element. Scandium is present in crustal rocks in amounts greater than lead and precious metals, but it rarely occurs in concentrated quantities because it does not combine into common ores or minerals.

Yttrium (Y) is chemically similar to the lanthanides and often occurs with other rare earths in the same minerals as a result of its similar ionic radius.

The lanthanides consist of 15 elements with atomic numbers 57 through 71. They are lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb) and lutetium (Lu).

Monazite is one of the most common minerals of rare earth elements.

Rare Earths Mining

Rare earths are a set of 17 chemical elements in the periodic table that, because of their unique geochemical properties, are typically widely dispersed in the Earth’s crust and are not often found in concentrated and economically exploitable forms. This fact requires special recovery and refining techniques to produce useable elements.

Rare Earths Uses

Significant quantities of rare earths are used in the production of clean energy technologies, including advanced automotive propulsion batteries, fuel cells, electric motors, high efficiency light bulbs and generators in wind turbines. Most modern defense technologies such as radar and sonar systems, precision-guided weapons, and cruise missiles require rare earths and the materials produced from them. Rare earths are also required in a variety of high tech applications in computing, pollution abatement, power generation, water treatment, oil refining, metal alloying, decolorizing recycled glass, communications, diagnostic health care, flat screen TVs, and hybrid cars.

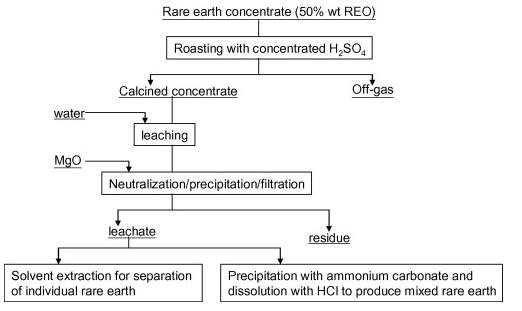

Rare Earths Mining Process

Rare earths are difficult to mine because they aren’t found in large quantities or veins like other minerals such as gold. They need to be separated from one another using a variety of mining and processing techniques.

There are three main methods for separating and refining the elements including: Fractional Crystallization, Ion-Exchange, Liquid-Liquid Extraction, or Solvent Extraction.

Most REE mines only produce these types of elements using large-scale techniques that involve drilling, blasting, and hauling.

The elements are separated and purified and then refined to meet industry standards for the proper applications.

JXSC Mining Processing

---Diamond Processing Plant---

8TPH Diamond Mining Process in Angola

18TPH Alluvial Gold & Diamond Mining Process in Angola

50TPH Alluvial Diamond Mining Process in Central African

50TPH Diamond Extraction Process Flow Chart

60TPH Alluvial Diamond Extraction Process in Venezuela

75TPH Diamond Dense Medium Separation Process in Congo

---Chrome Processing Plant---

1.2TPH Chromite Ore Beneficiation Process Flow

15TPH Chrome Ore Beneficiation Process in Ukraine

24TPH Chrome Ore Processing Plant in South Africa

25TPH Chromite Ore Concentrating Plant in South Africa

50TPH Chromite Ore Beneficiation Process in South Africa ---Silica Processing Plant---

50TPH Silica Sand Processing Plant in Indonesia

65TPH Silica Sand Washing Plant in Malaysia

100TPH Silica Sand Processing & Washing Plant in Malaysia

20TPH Beach Sand Mining Plant in India

100TPH Beach Sand Zircon Mining Plant in Sierra Leone

---Coltan Processing Plant---

10TPH Coltan Ore Mining Plant in Liberia

10TPH Alluvial Coltan Process Plant In Mozambique

20TPH Tantalum Niobium Mining Plant in Uganda

25TPH Tantalite Mining Plant in Burundi

100TPH Alluvial Coltan Processing Plant in Nigeria

100TPH Tantalite Ore Processing Plant in Sierra Leone

150TPH Coltan Ore Processing Plant in Ghana

---Lead, zinc, iron, manganese, etc---

15TPH Tailings Lead & Barite Extraction Plant in Iran

30TPH Rock Lead Zinc Process Plant in Morocco

200TPH Rock Manganese Mining Plant in Zambia

150TPH Iron Ore Processing Plant in Malaysia

8TPH Gold & Tin Extraction Process in Zimbabwe

10TPH Tin Ore Slag Beneficiation Processing Plant in Malaysia

50TPH Alluvial Tin Ore Mining Plant in Nigeria

3TPH Barite Beneficiation Process Plant in Morocco ---Gold Washing Plant---

0.5TPH Portable Hard Rock Gold Processing Plant in Sudan

0.5TPH Small Rock Gold Processing Plant In Sudan

1T/H Rock Gold Processing Plant In India

2TPH Quartzite Gold Wash Plant In Africa

2TPH Small Scale Rock Gold Processing Plant In Congo

4TPH Gold Ore Processing Plant In Zimbabwe

5T/H Rock Gold Processing Plant In Tanzania

5TPH Quartz Rock Gold Mining Process in Nigeria

10TPH Alluvial Coltan Process Plant In Mozambique

10TPH Copper Mining Process Plant In Zambia

10TPH Sulfide Gold Processing Plant In Ghana

20TPH Rock Contain Gold Mining Process in Zimbabwe 20TPH Alluvial Gold & Hard Rock Gold Processing Plant in Madagascar

30TPH Placer Gold & Rock Gold Wash Plant in Zambia

50TPH Gold Washing Plant In Uzbekistan

50TPH Alluvial Gold Mining Process In Ghana

50TPH Alluvial Gold Washing Plant In Sierra Leone

60TPH Wheel Mobile Gold Processing Plant In Mali 60TPH Gold Processing Plant In Russia

60TPH Mobile Alluvial Gold Wash Plant In Ghana

60TPH Small Portable Gold Wash Plant in Mali

75TPH Hard Rock Gold Mining Plant in Sudan

100TPH Clay Alluvial Gold Washing Plant In Ghana

100TPH Alluvial Gold & Diamond Processing Plant in Congo

100TPH Rock Copper & Cobalt Ore Process Plant In Congo

100TPH Tailings Copper & Zinc Process Plant In Kyrgyzstan

100TPH Gold Tailings Processing Plant In Uganda

100TPH Placer Gold Processing Plant In Kyrgyzstan

100TPH Alluvial Deposit Gold Processing Plant In Ghana

100TPH Alluvial Gold Wash Plant In Suriname

100TPH Alluvial Rock Gold Washing Plant In Mozambique 167THP Crusher Plant and 42TPH Rock Gold Processing Plant In Zimbabwe

200TPH Alluvial Gold Wash Plant In Ghana