Normal Temperature Pressure

Normal temperature desorption Electrolysis System

Gold extraction equipment

The normal temperature desorption electrolysis process of gold-loaded carbon is carried out at a desorption temperature of 95 10 (TC, normal pressure, pressure is 0.1 MPa, and the desorption liquid is sodium cyanide (NaCN) 2% + sodium hydroxide (NaOH) 1%, and the desorption cycle is More than 36 hours.

Equipment investment is small

Long desorption time

Operation is safe

High energy consumption

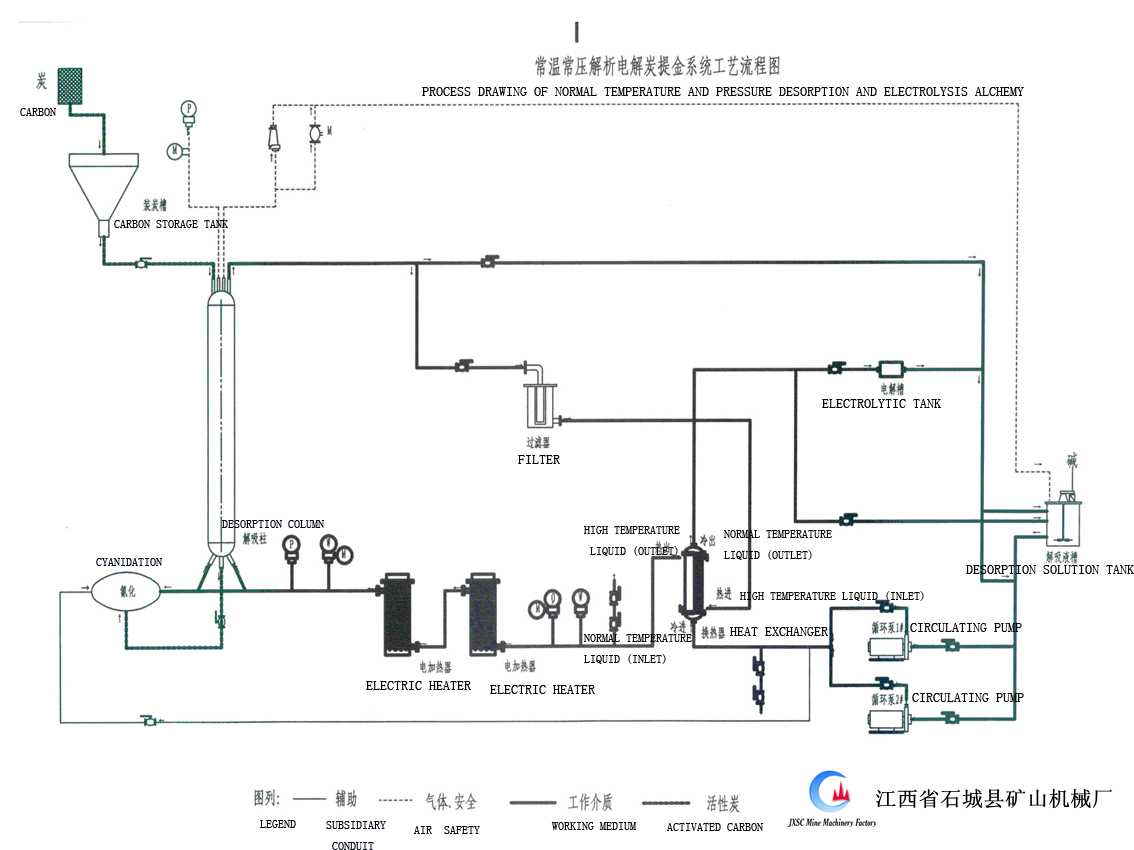

The normal Desorption electrolysis system process

The normal temperature desorption electrolysis process of gold-loaded carbon is carried out at a desorption temperature of 95 10 (TC, normal pressure, pressure is 0.1 MPa, and the desorption liquid is sodium cyanide (NaCN) 2% + sodium hydroxide (NaOH) 1%, and the desorption cycle is More than 36 hours, the advantage is that the equipment investment is small and the operation is safe; the disadvantage is long desorption time, low production efficiency and high energy consumption.

The high-temperature medium-pressure desorption electrolysis process of gold-loaded carbon, that is, the whole system pressure desorption electrolysis process was developed by Australian COMO ENGINEERS in the late 1980s. The gold-loaded desorption electrolysis process is at 150 ° C, 0.5 Mpa pressure. Desorbing and electrolysis at the same temperature and pressure, without using the toxic agent sodium cyanide, and the desorption time is only 8h; plus preheating and loading and unloading time, the gold and silver electrolysis time is about 10 12h than the atmospheric pressure desorption isotherm electrolysis process The saving time is about 50%. The cost of desorption and electrolysis of gold-loaded carbon is not lower than that of normal pressure desorption electrolysis without using sodium cyanide. Due to the above advantages, the whole system pressure desorption electrolysis process has been widely used in many mines at home and abroad. The disadvantages are large equipment investment, strict operation requirements, and troublesome maintenance and maintenance of pressure vessels.

Desorption electrolysis system equipment list

| No. | Equipment name | Unit | Qty | |||||

| 1 | Electrolytic Tank | SET | 1 | |||||

| 2 | Desorption Column | SET | 1 | |||||

| 3 | Filter | SET | 2 | |||||

| 4 | Electric Heater | SET | 2 | |||||

| 5 | Desorption Solution Tank | SET | 1 | |||||

| 6 | Carbon Storage Tank | SET | 1 | |||||

| 7 | Heat Exchanger | SET | 1 | |||||

| 8 | Liquid Storage Tank | SET | 1 | |||||

| 9 | Carbon Transporting Pump | SET | 2 | |||||

| 10 | Clean Water pump | SET | 1 | |||||

| 11 | Circulating Pump | SET | 1 | |||||

| 12 | Power Control Carbinet. | SET | 1 | |||||

| 13 | Power Control Carbinet. | SET | 1 | |||||

| 14 | Pipeline&valve | SET | 1 | |||||

| 15 | Instrument And Meter | SET | 1 | |||||