Mica Mining

What is Mica

Mica is a mineral name given to a group of minerals that are physically and chemically similar. They are all silicate minerals, known as sheet silicates because they form in distinct layers. Micas are fairly light and relatively soft, and the sheets and flakes of mica are flexible. Mica is heat-resistant and does not conduct electricity. There are 37 different mica minerals. The most common include: purple lepidolite, black biotite, brown phlogopite and clear muscovite.

Mica Mining

IMAR 7th Edition

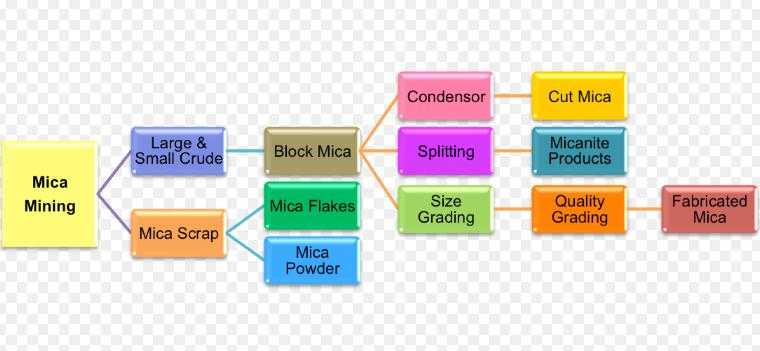

The mica industry can be divided into two distinct but interdependent industries: those that produce sheet mica, and those that produce flake mica. Each industry, although somewhat dependent on the other, produces different end products.

Sheet Mica Mining:

Sheet mica is recovered by either sinking a shaft along the strike and dip of a pegmatite or by open-pit surface mining of semi-hard pegmatite ore. In either case, it is a very economically risky mining procedure because of the cost involved in locating the vein and the unpredictability of the quality and quantity of the mica that might be recovered once the vein is located and worked.

In underground mining, the main shaft is driven through the pegmatite at suitable angles to the dip and strike using air drills, hoists and explosives. Crosscuts and raises are developed to follow promising exposures of mica. When a pocket of mica is found, extreme care is exercised in the removal to minimize damage to the crystals. Small explosive charges of 40% to 60% strength are carefully placed around the pocket and care is exercised with the drilling procedure so the mica will not be penetrated. The charge is just sufficient to shake the mica free from the host rock. After blasting, the mica is hand-picked and placed in boxes or bags for transporting to the trimming shed where it is graded, split, and cut to various specified sizes for sale.

Sheet mica is no longer mined in the U.S. because of the high cost of mining, the small market, and the high capital risk. Most sheet mica is mined in India, where labor costs are comparatively low.

Flake Mica Mining:

The flake mica produced in the U.S. comes from several sources: the metamorphic rock called schist as a by-product of processing feldspar and kaolin resources, from placer deposits, and from pegmatites. It is mined by conventional open-pit methods. In soft residual material, dozers, shovels, scrapers and front-end loaders are used in the mining process. North Carolina’s production accounts for half of total U.S. mica production. Hard-rock mining of mica-bearing ore requires drilling and blasting. After blasting, the ore is reduced in size with drop balls and loaded on the trucks with shovels for transport to the processing plant, where mica, quartz and feldspar are extracted.

Mica Uses

The principal use of ground mica is in gypsum wallboard joint compound, where it acts as a filler and extender, provides a smoother consistency, improves workability, and prevents cracking. In the paint industry, ground mica is used as a pigment extender that also facilitates suspension due to its light weight and platy morphology. The ground mica also reduces checking and chalking, prevents shrinkage and shearing of the paint film, provides increased resistance to water penetration and weathering, and brightens the tone of colored pigments. Ground mica also is used in the well-drilling industry as an additive to drilling “muds.”

The plastic industry used ground mica as an extender and filler and also as a reinforcing agent. The rubber industry uses ground mica as an inert filler and as a mold lubricant in the manufacture of molded rubber products, including tires.

Sheet mica is used principally in the electronic and electrical industries. The major uses of sheet and block mica are as electrical insulators in electronic equipment, thermal insulation, gauge “glass”, windows in stove and kerosene heaters, dielectrics in capacitors, decorative panels in lamps and windows, insulation in electric motors and generator armatures, field coil insulation, and magnet and commutator core insulation.

Mica Mining Process

JXSC Mining Processing

---Diamond Processing Plant---

8TPH Diamond Mining Process in Angola

18TPH Alluvial Gold & Diamond Mining Process in Angola

50TPH Alluvial Diamond Mining Process in Central African

50TPH Diamond Extraction Process Flow Chart

60TPH Alluvial Diamond Extraction Process in Venezuela

75TPH Diamond Dense Medium Separation Process in Congo

---Chrome Processing Plant---

1.2TPH Chromite Ore Beneficiation Process Flow

15TPH Chrome Ore Beneficiation Process in Ukraine

24TPH Chrome Ore Processing Plant in South Africa

25TPH Chromite Ore Concentrating Plant in South Africa

50TPH Chromite Ore Beneficiation Process in South Africa ---Silica Processing Plant---

50TPH Silica Sand Processing Plant in Indonesia

65TPH Silica Sand Washing Plant in Malaysia

100TPH Silica Sand Processing & Washing Plant in Malaysia

20TPH Beach Sand Mining Plant in India

100TPH Beach Sand Zircon Mining Plant in Sierra Leone

---Coltan Processing Plant---

10TPH Coltan Ore Mining Plant in Liberia

10TPH Alluvial Coltan Process Plant In Mozambique

20TPH Tantalum Niobium Mining Plant in Uganda

25TPH Tantalite Mining Plant in Burundi

100TPH Alluvial Coltan Processing Plant in Nigeria

100TPH Tantalite Ore Processing Plant in Sierra Leone

150TPH Coltan Ore Processing Plant in Ghana

---Lead, zinc, iron, manganese, etc---

15TPH Tailings Lead & Barite Extraction Plant in Iran

30TPH Rock Lead Zinc Process Plant in Morocco

200TPH Rock Manganese Mining Plant in Zambia

150TPH Iron Ore Processing Plant in Malaysia

8TPH Gold & Tin Extraction Process in Zimbabwe

10TPH Tin Ore Slag Beneficiation Processing Plant in Malaysia

50TPH Alluvial Tin Ore Mining Plant in Nigeria

3TPH Barite Beneficiation Process Plant in Morocco ---Gold Washing Plant---

0.5TPH Portable Hard Rock Gold Processing Plant in Sudan

0.5TPH Small Rock Gold Processing Plant In Sudan

1T/H Rock Gold Processing Plant In India

2TPH Quartzite Gold Wash Plant In Africa

2TPH Small Scale Rock Gold Processing Plant In Congo

4TPH Gold Ore Processing Plant In Zimbabwe

5T/H Rock Gold Processing Plant In Tanzania

5TPH Quartz Rock Gold Mining Process in Nigeria

10TPH Alluvial Coltan Process Plant In Mozambique

10TPH Copper Mining Process Plant In Zambia

10TPH Sulfide Gold Processing Plant In Ghana

20TPH Rock Contain Gold Mining Process in Zimbabwe 20TPH Alluvial Gold & Hard Rock Gold Processing Plant in Madagascar

30TPH Placer Gold & Rock Gold Wash Plant in Zambia

50TPH Gold Washing Plant In Uzbekistan

50TPH Alluvial Gold Mining Process In Ghana

50TPH Alluvial Gold Washing Plant In Sierra Leone

60TPH Wheel Mobile Gold Processing Plant In Mali 60TPH Gold Processing Plant In Russia

60TPH Mobile Alluvial Gold Wash Plant In Ghana

60TPH Small Portable Gold Wash Plant in Mali

75TPH Hard Rock Gold Mining Plant in Sudan

100TPH Clay Alluvial Gold Washing Plant In Ghana

100TPH Alluvial Gold & Diamond Processing Plant in Congo

100TPH Rock Copper & Cobalt Ore Process Plant In Congo

100TPH Tailings Copper & Zinc Process Plant In Kyrgyzstan

100TPH Gold Tailings Processing Plant In Uganda

100TPH Placer Gold Processing Plant In Kyrgyzstan

100TPH Alluvial Deposit Gold Processing Plant In Ghana

100TPH Alluvial Gold Wash Plant In Suriname

100TPH Alluvial Rock Gold Washing Plant In Mozambique 167THP Crusher Plant and 42TPH Rock Gold Processing Plant In Zimbabwe

200TPH Alluvial Gold Wash Plant In Ghana