Graphite Mining

Description

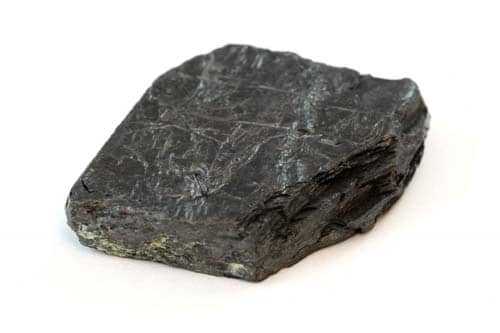

Pure graphite is a mineral form of the element carbon (element #6, symbol C). It forms as veins and disseminations in metamorphic rocks as the result of the metamorphism of organic material included in limestone deposits. It is an extremely soft mineral and it breaks into minute, flexible flakes that easily slide over one another. This feature accounts for graphite’s distinctive greasy feel. This greasy characteristic makes graphite a good lubricant. Because it is a solid material, it is known as a dry lubricant. This is useful in applications where “wet” lubricants, such as oil, cannot be used. Graphite is the only non-metal element that is a good conductor of electricity. Natural graphite is used mostly in what are called refractory applications. Refractory applications are those that involve extremely high heat and therefore demand materials that will not melt or disintegrate under such extreme conditions. One example of this use is in the crucibles used in the steel industry. Such refractory applications account for the majority of the usage of graphite.

It is also used to make brake linings, lubricants, and molds in foundries. A variety of other industrial uses account for the remaining graphite consumed each year.

| Type | Crystal System |

| Mineral | Hexagonal |

| Mineral Classification | Color |

| Native | Iron-black to steel-gray; deep blue in transmitted light |

| Chemical Formula | Luster |

| C | Metallic |

| Streak | Fracture |

| Black | Flaky |

| Mohs Hardness | |

| 1–2 |

Relation to Mining

IMAR 7th Edition

From 1890 to 1920, underground mining of graphite was practiced in New York and Pennsylvania. From 1942 until the end of World War II, only open-pit methods were used, because working weathered rock was relatively easy. Graphite was mined underground at Dillon, Montana, during World War II, but shortly thereafter mining ceased because it was too costly to compete with Sri Lankan graphite.

Madagascar operations are entirely open pit, but in Bavaria, Korea, Mexico, and Sri Lanka, because of the depth and physical characteristics of the deposits, underground mining is practiced. Mexican underground mining operations are 100–400 m below the surface, measured on the angle of the vein. Some of the older mines in Sri Lanka reached depths in excess of 450 m on a vertical plane. For many years, mining operations in Sri Lanka were primitive and ore extraction was slow and cumbersome. The mines were mechanized after World War II.

Madagascar operations also were primitive because low labor costs prohibited mechanization. After 1938 the mines began to use mechanical equipment to remove the overburden, and bulldozers and tractors easily removed the graphite-bearing schists.

Worldwide demand for graphite steadily increased throughout 2012 and into 2013. This increase resulted from the improvement of global economic conditions and its impact on industries that use graphite.

Principal import sources of natural graphite were, in descending order of tonnage, China, Mexico, Canada, Brazil, and Madagascar, which combined accounted for 97% of the tonnage and 90% of the value of total imports. Mexico and Vietnam provided all the amorphous graphite, and Sri Lanka provided all the lump and chippy dust variety. China, Canada, and Madagascar were, in descending order of tonnage, the major suppliers of crystalline flake and flake dust graphite.

During 2013, China produced the majority of the world’s graphite. Graphite production increased in China, Madagascar, and Sri Lanka from that of 2012, while production decreased in Brazil from 2012 production levels.

Uses

Because graphite flakes slip over one another, giving it its greasy feel, graphite has long been used as a lubricant in applications where “wet” lubricants, such as oil, can not be used. Technological changes are reducing the need for this application.

Natural graphite is used mostly in what are called refractory applications. Refractory applications are those that involve extremely high heat and therefore demand materials that will not melt or disintegrate under such extreme conditions. One example of this use is in the crucibles used in the steel industry. Such refractory applications account for the majority of the usage of graphite.

It is also used to make brake linings, lubricants, and molds in foundries. A variety of other industrial uses account for the remaining graphite consumed each year.