Diamond Mining Equipment

Diamond mining equipment normally in the process like first use vibration feeder to feeding material to trommel scrubber, After trommel scrubber for washing clean, and separator big size out, then to vibration screen. Vibration screen also for separator different sizes. The equipment includes trommel scrubber, vibrating screen, jig concentrator, slurry pump, magnetic separator, hydrocyclone, and the other mining equipment.

Diamond mining process

Dense media separation

The beneficiation methods for diamond primary ore and placer of diamond have own similarities and differences, but basically, they can be divided into two stages, i.e. roughing and concentration. Rough is achieved mainly by gravity separation with the jigging machine; while concentration is conducted by various methods jointly. Quality is important during the entire beneficiation process. The quality inspection should be taken in each step with various methods on the different quality requirements for each grade. The required total recovery rate for diamond is not less than 95%.

Diamond is a rare and valuable mineral resource. Mineral processing is currently the only effective method for determining the diamond content in the ore. The purpose of diamond beneficiation is to dissociate and select the monomeric diamond from the ore and recover the gold-associated minerals as much as possible. JXSC diamond mining equipment assists you to bring greater profit.

1. Diamond mining stages

The ore dressing is divided into two stages: rough and concentration.

1.1 Rough selection

The rough selection operation is mainly carried out by the jigging machine. The upper limit of the selected particle size is 16 mm, and the lower limit of the recovery particle size is 0.2 mm.

(1) Primary ore: firstly crushing and grading (weathering samples need to be pre-screened), then jigging and sorting. The jigging tailings enter the grinding operation, then dissociate the undissociated diamonds. After dissociation Return to the jigging sorting cycle several times until the ore is ground to the lower limit of the selected particle size.

In the samples with strong weathering, it usually contains more clay and has a strong bonding effect. Before the sorting, it is necessary to carry out washing and pre-screening before selection. ore crushing and desliming procedure to prevent loss and breakage of diamonds.

(2) Sand ore: In the sand ore, the diamond particles are present in the form of monomer and loose sand or glued with clay. The coarse concentrate can be obtained after these processes: washing, sieving, grading and desliming, separating the large gravel and fine mud tailing, clean sand jigging separation.

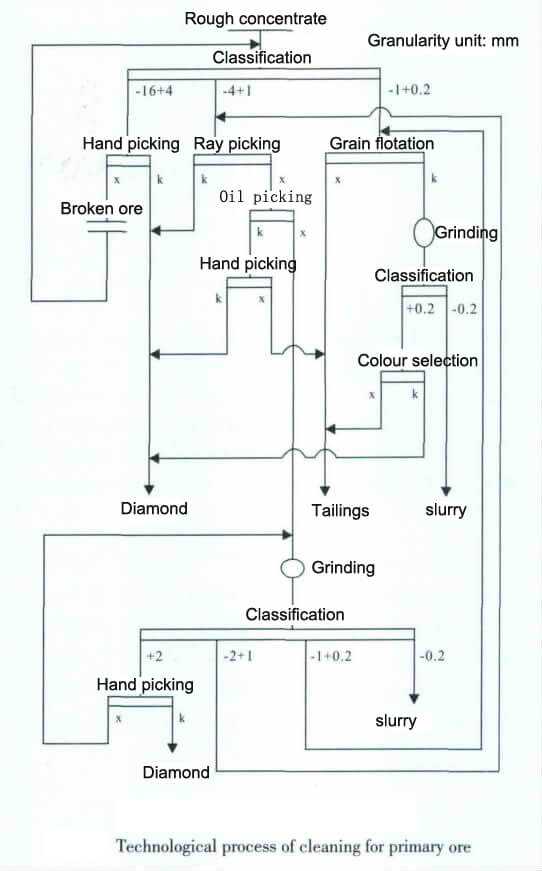

1.2 Concentration

According to the nature of diamond and coarse concentrate, the concentration selection operation is carried out in a combination of various methods. Generally, >4mm by hand picking, -4+1mm by X-ray separation or oil separation, -1+0.2mm by particle floatation, shaker table, magnetic separation, gravity separation, selective grinding, alkali fusion, heavy liquid separation and microscopic selection. the tailings of concentrate sand ore are generally discarded.

The tailings of primary ore concentration which bigger than 0.5mm need to be re-grinding, if <0.5mm, discard it.

2. Diamond mining process equipment

Diamond recovery index: total recovery, ≥95%; +2 mm, 100%; -2 +1 mm, ≥98%; -1 +0.5 mm, ≥ 92%; -0.5+0.2 mm, ≥85%.

- Ore washing

(1) Net sand content in waste rock (not exceeding 1%): using the grid method.

Sampling in the waste rock pile or using the method of regular access during the washing process. The weight of the sample should be determined according to the diameter of the waste rock, generally 100-200 kg.

Firstly, weight the waste rock (surface wetting), then put into the panning sieve basin to clean it, and all the materials smaller than the washing mesh hole are leaked into the sieve, and then weight the washed waste stone.

(2) The amount of mud in the net sand (not to exceed 5%): Select several points in different parts of the net sand, and take a representative inspection sample, generally take 5 to 10 kg. After weighing the test sample, in a water-filled container, wash it with a sieve with a screen size of 0.2 mm, and filter and weigh it.

(3) The overflow water is larger than 0.2 mm. The particle size (not more than 1%): use the iron spoon to regularly take the overflow water and pour it into the basin. After the sedimentation, remove the water and remove the slime 2 kg from it. The sieve is sieved into a 0.2 mm sieve and weighs the material on the sieve. - Crushing

Based on the mechanical fracture rate of diamond, in order to protect the crystal integrity of the diamond, it is required to reduce the diamond mechanical fracture rate of the crushing operation to a minimum. The quality of the crushing operation is indirectly measured by the size of the discharge port that directly affects the diamond breaking rate. - Grinding

It is measured by the grinding concentration and adjusted by the actual diamond breaking rate. Generally, the concentration of the new hard ore is about 75%; when the weathered soft ore is treated, the concentration can be appropriately reduced to about 65%. - Screening

- Dehydration

The thick bucket must not exceed 70% of its volume. - Jigging machine

(1) Indirect method: In the jigging machine operation, directly put diamond or indicator mineral (glass specific gravity ball), the number of diamonds added each time is 5 to 10, and the number of glass spheres added is 10-20. The recovery rate is calculated as a single sample and must not be less than 95%.

(2) Direct method: Partial or full sampling of the jigging tailings, re-checking the jigging. Check the diamond loss in the tailings to calculate the recovery rate of the jigging operation.

(3) Heavy liquid method: directly sample in the jigging tailings, float and sink in the heavy liquid, calculate the content of heavy minerals. Similarly, the content of heavy minerals in the raw materials can be determined, and the actual recovery of heavy minerals can be calculated by the calculation rate. - Hand selection

(1) Directly put diamond or indicator minerals, the recovery rate should be 100%.

(2) The hand-selected tailings shall be checked by X-ray or by hand. The actual diamond recovery rate shall be 100%, and the recovery rate of the main associated minerals shall not be less than 98%. - X-ray selection

(1) Directly place diamond or indicator mineral (lighting mineral) in the sample, add 10~15 each time. Calculate the recovery rate according to the sample, not less than 98%.

(2) The x-ray selected tailings are selected by hand selection, oil selection or X-ray inspection. - Oil selection

(1) Directly put diamond or indicator mineral, the recovery rate according to the sample shall not be less than 98%.

(2) Oil-selected tailings shall be inspected by X-ray selection, selective grinding, etc. The actual recovery rate of diamond in the sample shall not be less than 95%. - Grain floating

(1) Directly placing diamonds, adding no less than 5 diamonds each time, the recovery rate shall not be less than 98%.

(2) From the selection of grinding, alkali fusion or particle floating mutual inspection, the diamond recovery rate is 95% or more according to the sample. - Magnetic separation

X-ray selection (materials larger than 1 mm), particle floatation and grinding, etc., the actual recovery rate of diamond should not be lower than 95%. - Shaker table

(1) Adding a diamond or indicating mineral inspection, the recovery rate shall not be lower than 95%.

(2) The shaker tailings are inspected by means of particle floatation or selective grinding. The actual recovery rate of the diamond is not less than 95% according to the sample. - Comprehensive quality inspection of sand samples

(1) Adding a glass specific gravity ball to the extracted sand ore sample and the net sand sample, and then recovering from the coarse concentrate of the jigging operation, respectively checking the original sample transportation, washing, sand transportation and jig sorting operations, etc.

(2) In the exploration stage of the deposit, diamond (weighed, described) is added to the sample of the mined sand, and then recovered from the X-ray and hand-selected concentrate to check the quality of the whole process of the sorting operation. The sample is filled with a glass specific gravity ball and diamond for quality inspection. The recovery rate of a single sample shall not be less than 95%.

- Ore washing

3 Diamond mining plant summary

(1) Diamond is mainly produced in kimberlite. The content of heavy minerals in kimberlite varies with kimberlite type and origin, but most of them (about 99%) have lower specific gravity than diamond. Therefore, a heavy selection method is one of the effective methods for diamond ore sorting.

(2) Jigging ore dressing is a gravity separation method that uses the difference in specific gravity between minerals. It does not need to add any chemicals, so there is no chemical pollution in the beneficiation process. The practice of many years shows that the effect of jigging and sorting is good. The process is simple, and the operation and management are convenient. Especially in the geological experiment stage, it shows the advantages of high recovery rate and light equipment, which is a method widely used at home and abroad.

(3) The basis of the diamond mining equipment selection is the physical and chemical properties of the mineral, such as color, gloss, hardness, specific gravity, shape, particle size, magnetic permeability, electrical conductivity, surface wettability, wear resistance, etc. The method is reliable and the effect is good. contact us to get the latest price of diamond mining equipment and diamond process flowsheet. JXSC is 30+ years of mining equipment suppliers in South Africa.