Feldspar Mining Process

What is Feldspar

Feldspar is the name given to a group of minerals distinguished by the presence of alumina and silica (SiO2) in their chemistry. This group includes aluminum silicates of soda, potassium, or lime. It is the single most abundant mineral group on Earth. They account for an estimated 60% of exposed rocks, as well as soils, clays, and other unconsolidated sediments, and are principal components in rock classification schemes. The minerals included in this group are the orthoclase, microcline and plagioclase feldspars.

Feldspar Mining

The top states producing feldspar are North Carolina, Virginia, California, Oklahoma, Idaho, Georgia and South Dakota, in descending order of estimated tonnage. Feldspar processors reported co-product recovery of mica and silica sand.

Feldspar is mined from large granite bodies (called plutons by geologists), from pegmatites (formed when the last fluid stages of a crystallizing granite becomes concentrated in small liquid and vapor-rich pockets that allow the growth of extremely large crystals), and from sands composed mostly of feldspar.

Because feldspar is such a large component of the Earth’s crust, it is assumed that the supply of feldspar is more than adequate to meet demand for a very long time to come. Present mines worldwide are adequately meeting the need for raw feldspar.

Hard-rock mining for feldspars is done by open-pit methods, either by the mine owner or by contractors. After the feldspar ore is drilled and blasted, secondary breakage is performed with a conventional drop ball. Ore is then loaded with a hydraulic shovel onto trucks and hauled to the crushing plant, which is adjacent to the flotation plant.

Uses: Feldspar is used to make dinnerware and bathroom and building tiles. In ceramics and glass production, feldspar is used as a flux. A flux is a material that lowers the melting temperature of another material, in this case, glass.

Substitutes and Alternative Sources

Feldspar can be replaced by other minerals and mineral mixtures of similar physical properties. Minerals that could be used to replace feldspar include pyrophyllite, clays, talc, and feldspar-silica (quartz) mixtures. The abundance of feldspar will make these substitutions unnecessary for the foreseeable future.

Feldspar Uses

Feldspar is used to make dinnerware and bathroom and building tiles. In ceramics and glass production, feldspar is used as a flux. Flux is a material that lowers the melting temperature of another material, in this case, glass.

Substitutes and Alternative Sources

Feldspar can be replaced by other minerals and mineral mixtures of similar physical properties. Minerals that could be used to replace feldspar include pyrophyllite, clays, talc, and feldspar-silica (quartz) mixtures. The abundance of feldspar will make these substitutions unnecessary for the foreseeable future.

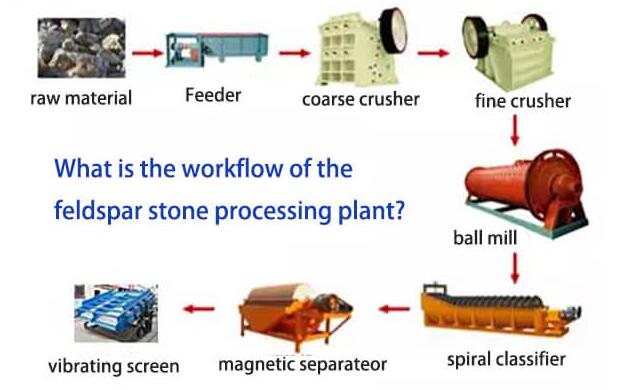

Feldspar extraction processing plant

1. Crushing and grinding

The crushing and grinding of feldspar are not only to meet the grain size requirement of the final product, but also to meet the need of the impurity removal process. The coarse crushing of feldspar mostly adopts jaw crusher, and the particle size is about 10mm. There are many options for fine crushing and grinding machines of the feldspar processing plant, mainly roller crusher, impact crusher, sand making machine, hammer crusher, stone grinding, column mill, tower mill, Raymond mill, stirring mill, vibration mill, sanding mill, and airflow mill, etc.

At present, feldspar grinding can be divided into dry grinding and wet grinding, wet type grinding is more efficient than dry type.

From the point of view of the application industry, the processing of feldspar raw materials in the glass industry mostly adopts a steel rod medium grinding machine, which has high grinding efficiency and uniform particle size, but the introduction of iron pollution leads to the low quality of feldspar products. The ceramic industry has higher requirements for feldspar raw materials, so stone roll grinding or ceramic ball grinding is often used, which has low grinding efficiency and high energy consumption, and can not realize high efficiency and continuous process.

On the basis of ensuring the high quality of feldspar products, how to realizing high efficiency grinding process and continuous production is an important subject in the research of feldspar beneficiation and purification.

2. Ore washing and desliming

The washing process is suitable for feldspar produced from weathered granite or feldspar placer, which mainly to remove impurities such as clay, fine mud and mica. On the one hand, it can reduce the content of Fe2O3 in feldspar ore, on the other hand, it can increase the content of potassium and sodium in feldspar ore.

Common ore washing machines: Denver washer dryer, vibrating screen, log washer, mixing tank, and grinders.

Desliming is mainly used to remove the primary slime and the secondary slime produced by grinding, prevent a large amount of fine slime from affecting the separation effect of subsequent operations such as flotation and magnetic separation. Commonly used equipment desliming hopper, centrifuge concentrator, hydrocyclone, etc.

3. Magnetic separation

Due to the magnetic properties of iron minerals, mica and garnet in feldspar ore, it can be separated from feldspar mineral by the external magnetic field. In general, the magnetic properties of iron minerals and mica in feldspar are weak, only by using high-intensity magnetic separator can get a good result. The main magnetic separator equipment has a permanent magnetic roller type strong magnetic separator, permanent magnetic drum type medium strong magnetic separator, wet flat type strong magnetic separator and high gradient strong magnetic separator.

4. Flotation

Flotation is an effective way to remove impurities in feldspar. On the one hand, the impurity elements such as iron and titanium can be removed from feldspar, the combination of chemical agents depends on the existing components of impurity; on the other hand, the feldspar can be separated out the quartz, thus increase the content of K, Na.

At present, there are many studies on the separation of feldspar and quartz, as well as the selective separation of potassium feldspar and albite.