Trommel Scrubber

Gold trommel scrubber is widely used for cleaning various kinds of difficult-to-wash bulk ore, stone, sand & gravel, it is divided into cylinder type and plus screening strip type, the latter can process fine and coarse feed simultaneously, remove or classify the feeding material according to the particle size, +40mm and -40mm. The feed which size -40mm then can be divided into +2mm and -2mm by double spiral trough ore washer, final ore washing efficiency could up to 98%, this combination of gold trommel scrubber and spiral ore washer is the most effective method for hard to wash ores.

JXSC Trommel Crubber

We have two types of gold trommel: mobile type with wheel and fixed types. Capacity: 1-250TPH

Features:

1. Good function of washing clay, screening ores.

2. High production capacity ( can be from 1T/H to 250 T/H) & efficiency.

3. Low operating costs, easy maintenance, and low noise.

4. The length & diameter of the drum, screen mesh, layer quantity of screen can be customized.

5. It can be made a mobile type or stationary type.

6. Can Operating with other mining machines.

7. The inside drum can be lined with rubber plates or welded with steel material spiral plates.

8. The screen material can be PU or manganese or stainless steel

9. With Rubber tires driving, water spray pipes inside the screen.

10. It can be with an electric motor or diesel generator.

3 kinds of trommel screens: PU screen, manganese steel screen, and stainless steel screen.

Processible Material:

All kinds of sticky clay material, include: alluvial gold / tin ore/ tungsten ore/ chrome ore/ coltan ore/ beach sand/ zircon sand/ diamond/iron sand/manganese ore/silica sand/ kaolin clay/ gravel stone, etc.

The building industry uses sand & gravel, light industry uses clay, kaoline.

Brief Introduction:

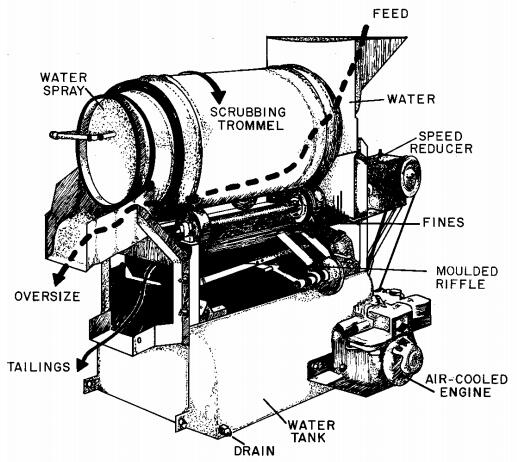

Trommel scrubber washing machine, also known as rotary trommel scrubber, drum scrubber trommel, is the main washing equipment in the mining industry, widely used for washing alluvial type/sand type ores and stones, that with much sticky clay, with much good washing effect for clay. The washing process is usually the preparation for crushing and beneficiation.

Main parts: drum scrubber, screen, and high-pressure sprinkler. The drum rubber is for washing ore, the screen is for sieving different size particles after washing, and the high-pressure sprinkler is helping material to shatter.

Working Principle

Tech Specification

| Model | Screen Size (MM) | Rotation Speed(R/Min) | Feeding size (mm) | Angle of inclination (degree) | Capacity (T/H) | Power (KW) |

| JXSC-400 | ≤20 | 27.9 | ≤80 | ≤10 | 1-5 | 3 |

| JXSC-600 | ≤25 | 27.6 | ≤80 | ≤10 | 5-10 | 5 |

| JXSC-750 | ≤25 | 27.6 | ≤100 | ≤10 | 10-30 | 7.5 |

| JXSC-900 | ≤25 | 27.6 | ≤100 | ≤10 | 30-50 | 11 |

| JXSC-1200 | ≤25 | 17 | ≤160 | ≤10 | 50-70 | 15 |

| JXSC-1500 | ≤50 | 16 | ≤230 | ≤10 | 70-100 | 30 |

| JXSC-1800 | ≤50 | 16 | ≤230 | ≤10 | 100-150 | 37 |

| JXSC-2100 | ≤50 | 16 | ≤230 | ≤10 | 150-180 | 45 |